DPAS offers a broad range of features and functionality to enable you to improve efficiency, reduce your maintenance costs, and provide accounting best practices. The DPAS asset management system is an approved accountable property system of record.

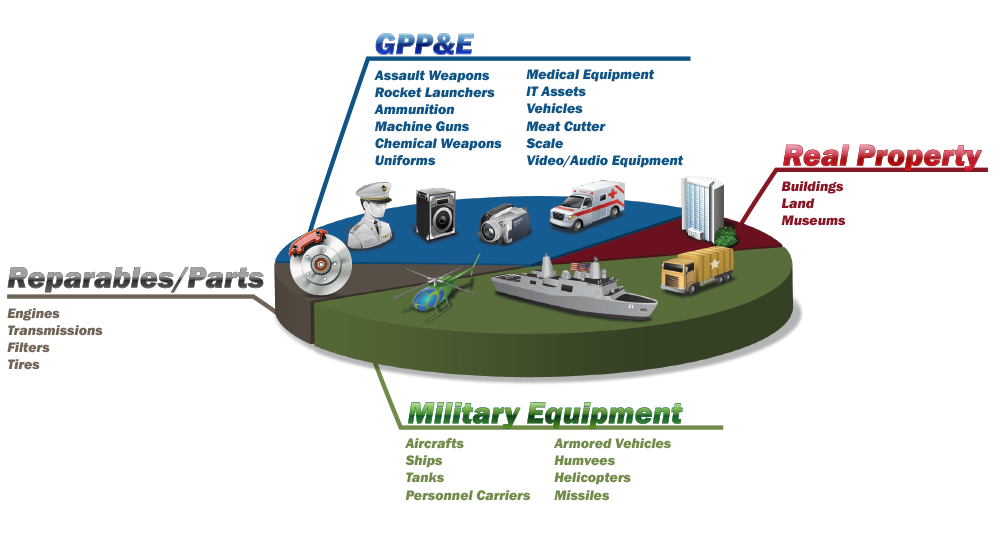

With DPAS, you can provide accountability for...

- General Property, Plant & Equipment (Personal Property)

- Military Equipment (ME)

- Government Furnished Property and Equipment (GFP&E)

- Real Property / Stewardship Land

- Heritage Assets

- Reparables/Parts

DPAS Asset Management Capabilities Include...

- Due In tracking

- WAWF Interface

- IUID Management and an interface with the IUID Registry

- Generate Virtual UID and maintain manufacturers assigned UIDs

- Report Virtual UID to Registry to become a permanent UID

- Print UID Labels

- Life Cycle Management from Receipt, to Update and Inventory, Transfers, and Disposal

- Interface with DRMO via DAISY

- Track excess

- Automatically dispose assets when DRMO processes transactions

- Assets assigned to Custodian, the person signing for equipment

- Attach documents such as pictures, contracts, warranty, invoice, DD250, DD1149, etc.

- Serial Number or Bulk Quantity tracking

- Track Components to End Items

- Group assets as part of a System (System ID)

DPAS Maintenance & Utilization Capabilities Include...

- Profile Property Accountability assets for maintenance and utilization

- Schedule Preventive Maintenance for assets

- Establish Work Plans to ease the creation of Preventive Maintenance Schedules and Work Orders

- Create Work Orders to track the Maintenance of assets

- Set up Equipment Pools to group assets

- Manage extended warranties, equipment purchases, subscriptions, and maintenance/service agreements

- Create Terms and Conditions Clauses for warranty/service/subscriptions

- Associate assets to warranty contracts

- Update utilization data

DPAS Warehouse Management Capabilities Include...

- Managing both serialized and bulk equipment which are durable or consumable

- A four-tier structure: Logistics Program – Region – Site – Warehouse

- A shared Catalog across Warehouses

- Warehouses can be subdivided into Facilities, Zones, Locations and Containers

- Grouping equipment by Commodity Type

- Shelf Life Management of equipment

- The use of Master Issue Lists to help the speed and accuracy when issuing standardized equipment

- Individual or Unit Issues and Returns

- Material Release Orders for manual or externally managed items

- Warehouse transfer to support replenishment

- Three types of Dispositions (Local, Excess and Warehouse Turn-In)

- Sets, Kits and Outfits Management

- A Quality Control process which includes the ability to send items to an associated M&U Maintenance Activity

- The use of Automatic Identification Technology (AIT) for Receipts, Picks (Moves), Shipping, Inventories, Quality Control and Inquiries

- Ability to assign Personnel to specific tasks

- Integrated Inventory processes

For more details on Warehouse Management, Check out the WM Overview Presentation.